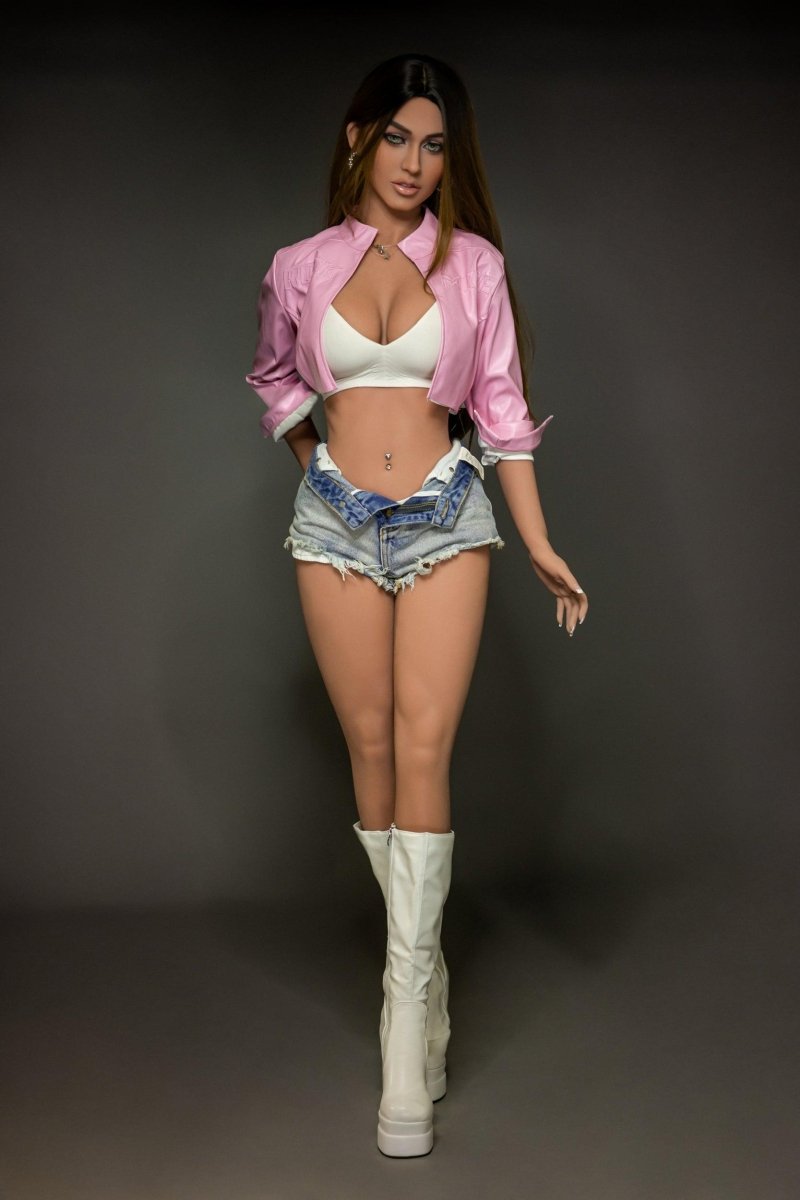

What is TPE?

TPE, or Thermoplastic Elastomer, is a versatile polymer blend known for its elastic and flexible properties. Here's a brief overview:

Composition: TPE is a class of copolymers, combining the characteristics of plastic and rubber. It is created through a blend of polymers, resulting in a material that exhibits both thermoplastic and elastomeric properties.

Elasticity: One of the key features of TPE is its elasticity, making it highly flexible. This allows TPE to return to its original shape after deformation, providing durability and resilience.

Applications: TPE is widely used in various industries due to its versatility. It is commonly found in consumer products, automotive parts, medical devices, and more. TPE is chosen for its ease of processing and ability to meet specific application requirements.

Processing: TPE can be processed using various methods such as injection molding and extrusion. This makes it suitable for manufacturing products with intricate shapes and designs.

Advantages: TPE offers advantages such as soft-touch feel, weather resistance, and recyclability. It is a popular choice for applications requiring a balance of flexibility and durability.

Common Products: TPE is used in the production of everyday items like grips on tools, seals, toys, medical devices, and kitchen utensils. Its widespread use highlights its adaptability to different manufacturing needs.

Maintenance: TPE products are generally easy to maintain. Cleaning with mild soap and water is often sufficient, and they can withstand a range of environmental conditions.

In summary, TPE is a valuable material appreciated for its combination of plastic and rubber properties. Its broad applications across industries make it a go-to choice for manufacturers seeking a flexible and resilient material.